Did you know that concrete is the second most-consumed resource after water?

Did you know that concrete is the second most-consumed resource after water?

Think of your home, parking lots, bridges, or any other public utility building and you will find concrete.

Unfortunately, this has also resulted in the concrete industry becoming one of the biggest emitters of greenhouse gases. In fact, if the concrete industry were a nation, it would be the third-largest emitter of carbon dioxide, after China and the United States.

Let’s “cement” our knowledge of concrete, why it generates greenhouse gases, and a new alternative called “green cement” which cuts emissions.

A Brief History of Concrete

Cement has existed long before humans have and formed naturally 12 million years ago when limestone reacted with shale. Around 6500 BCE, concrete was the key to the survival of the ancient Nabataeans in the harsh deserts of Syria and Jordan, who built structures that still stand today.

Concrete also transformed Roman architecture with arches and designs, which would have been impossible to achieve with stone.

Concrete also transformed Roman architecture with arches and designs, which would have been impossible to achieve with stone.

In 1756, the British engineer John Smeaton added pebbles and powdered brick into cement to create the first modern concrete. Later in 1824, English scientist Joseph Aspdin invented a much stronger cement than ever before by burning ground limestone and clay together. This mixture is called Portland cement, a recipe still in use today.

Modern concrete is a mixture of water, an aggregate of rock, sand or gravel, and Portland cement. Cement is the binding agent that gives concrete its strength and durability, protecting it from rust, rot, and fires. Concrete structures are resistant to high temperatures and water, are economical, and require low or zero maintenance.

The Sydney Opera House and the Pantheon, the largest unsupported concrete dome in the world, are beautiful structures made from concrete.

What is Green Cement?

In 2016, 2.2 billion metric tonnes of CO2 were emitted from cement production - much more than emissions from the airline industry and fairly close to emissions from the agricultural industry.

Cement industry leaders have pledged to reduce annual emissions by at least 16% by 2030 in order to meet the requirements of the Paris Climate Agreement on climate change.

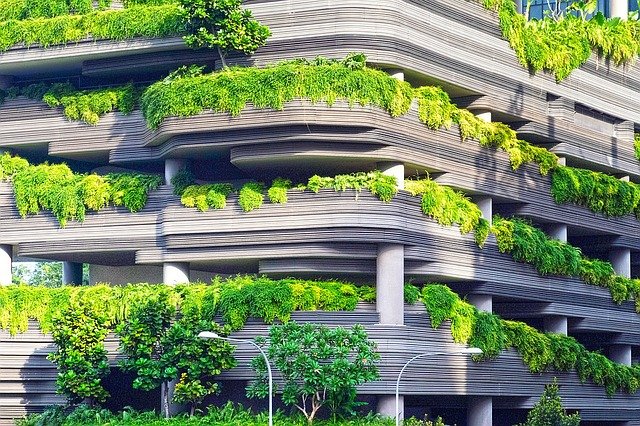

Green Cement is a form of cement produced through manufacturing processes that drastically reduce carbon emissions. One way is to capture the greenhouse gases and pump them underground. Others are looking at entirely new ways of making cement.

- BioMason is a company that makes bio-concrete bricks using sand and bacteria, similar to the process used to build coral. The entire process of building these bio-bricks takes place at room temperature in only four days, without the use of fossil fuels.

- Another company, LC3, takes a page from the Romans and substitutes some of the cement with ash or clay. This process reduces CO2 emissions by 40% while maintaining the strength of concrete.

- Other companies such as Cemex, are looking into replacing cement with aluminosilicates, which will make the concrete very strong, but more expensive.

- Finally, a team of researchers in Australia have experimented with a carbon-neutral magnesium oxychloride cement (MOC). MOC is made from byproducts of the magnesium mining industry, which are plentiful in Australia and China. It can also be made from seawater. MOC is stronger and can be made much faster than conventional cement.

With all the recent advancements in the green cement industry, the future looks bright as scientists continue to develop a stronger, cheaper, and carbon-negative alternative to conventional concrete.

Sources: BBC, Carbon Brief, The Conversation